Metrology Solutions

Nanotech Test & Measurement Solution provides X-ray and Computed Tomography systems having various range, specifications and configuration. X-rays with Computed Tomography systems give deep insights into the inside & allowing users to visualize, analyze and measure internal components, surfaces and complex geometry, all non-destructively.

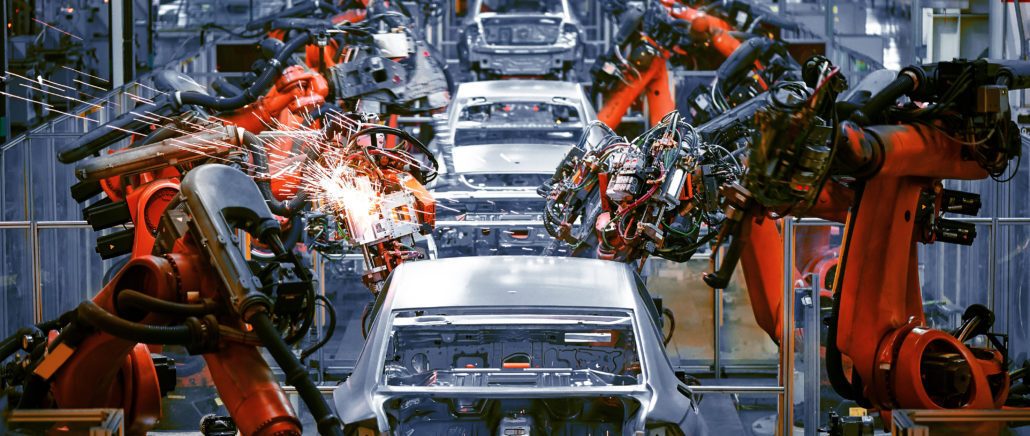

We provide solutions for R&D and Production purpose which suits a wide application in various industries such as aerospace, automotive, manufacturing, electronics, castings, plastics, consumer products and much more.

Our system has a wide range starting from 100kV through to 450kV. The system with Sample Rotating technology allows superior image quality in 2D X-ray and 3D

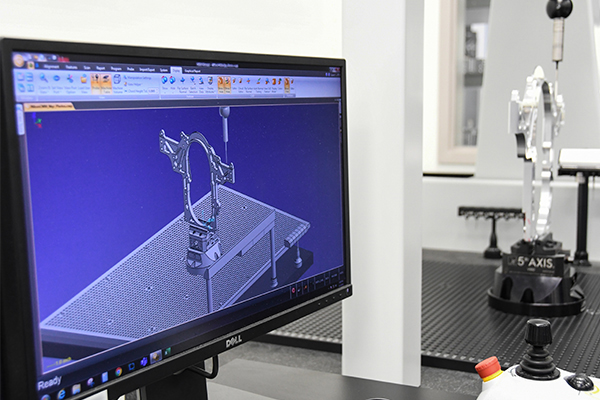

Ours CMM & handheld laser scanners enable a digital inspection process that reduces time-to-market and cuts development costs. Ours designed arm system provides high-speed productivity & highly precise metrology with contact & non-contact type. The systems optimize the manufacturing plant production workflow through rapid, reliable and accurate analysis of freeform features and product dimensions. Those systems are already proven an invaluable tool for rapidly diagnosing issues in all areas of manufacture, from the shop floor to the metrology lab.

Benefits of Laser Scanning:

Discover how laser scanning provides time and cost advantages in production engineering and how manufacturers can benefit from better insights, earlier…

- Laser scanning provides highly effective inspection

- Keeping down costs

- Better insight enables quicker decision-making

- Challenging surfaces scanned easily

- Non-contact is ideal for fragile or flexible surfaces

- Automation-ready for production environments Automation-ready for production environments

From small to large scale, we provide superior quality in Ceramic CMM’s including Bridge, Gantry and Horizontal arm models.

Ours Coordinate Measuring Machines represent the ultimate in CMM technology. Designed and manufactured using only the highest quality materials, they carry a heritage of over 45 years’ experience and expertise. Our products deliver the ability to perform dimensional, positional and surface measurement in a single system. Combined with a complete range of contact and non-contact sensors, this CMMs provide true multi-sensor capability. Sensors can be quickly changed to combine geometric and surface measurement into a single inspection routine.

Bridge CMM: Those CMM is ceramic bridge based CMM with high speed, high accuracy multi sensor measuring systems for mall to large components.

Gantry CMM: Those CMM benefits from an ultra- stiff frame to deliver high throughput, high accuracy dimensional inspection of very large components.

Horizontal arm CMM: The multi sensor horizontal arm CMM’s provide unequalled performance in speed, accuracy & repeatability for car body and component inspection.

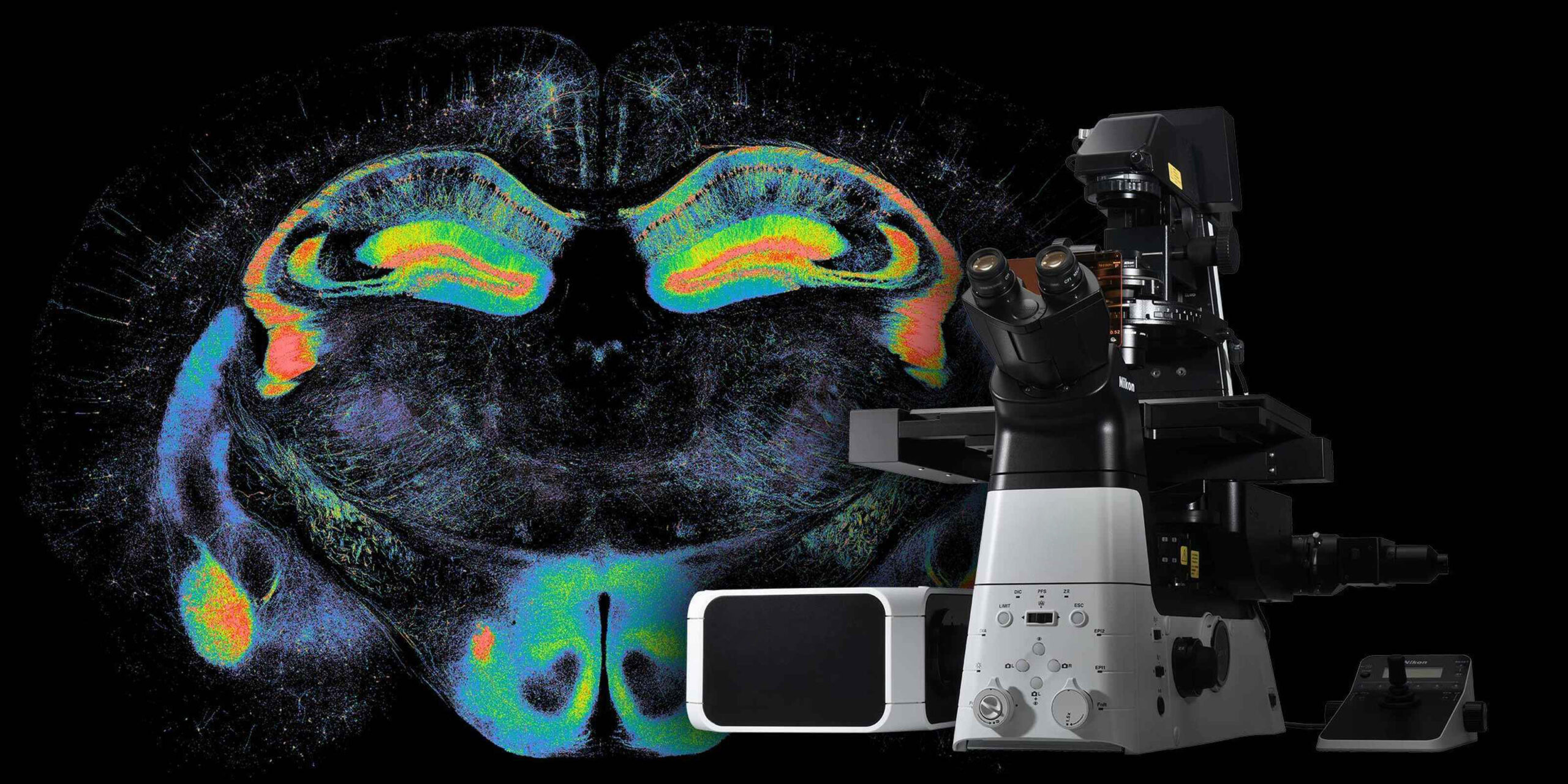

Nanotech Test & Measurement Solution offers Stereozoom Microscope, Metallurgical Microscope & Measuring Microscope with various specifications to meet a wide range of applications.

Stereozoom Microscope: Our Seterozoon Microscope provides accurate & precision optics, having large zoom ranges and wide fields of view for analyzing the wide range of Test samples in two and three dimensions. We offer a broad range of Stereo Microscopes & Accessories including a research Stereo Microscope System with the world’s highest Zoom ratio, superb resolution & bright fluorescence imaging. Also features other versatile parallel optics type models suitable for various applications and Greenough-type models that are user-friendly and affordable.

Metallurgical Microscope: We offer a wide range of Metallurgical Microscopes which provides detailed metallurgical application. Through those, we can perform Surface Inspection, Micro Structure Analysis, and Automated Image Analysis applications. The features involved in the observation are Bright Field, Dark Field, Simple Polarizing, DIC, Fluorescence observation and motorized turret.

Measuring Microscope: Measuring Microscope is a new and innovative series microscope system that offers versatility, high reliability and an exceptional level of precision and durability. Those microscopes are designed for all industrial measurement and image analysis applications, focusing particularly on repeatable data capture- all with an easy user workflow.

Nanotech test & Measurement Solution is a multi-sensor video measuring system for tactile, video and laser-based inspection. Available from small to ultra-wide working volumes, excellent edge technology and a variety of optical heads and illumination options make our system suitable for automated measurements & many other applications like large FOV, and long XYZ stroke.

We offer the VMS system which is designed & developed for non-contact inspection and measurement. Designed to meet demanding manufacturing requirements with automated measurements of mechanical parts, electronic devices, dyes & moulds and medical devices.

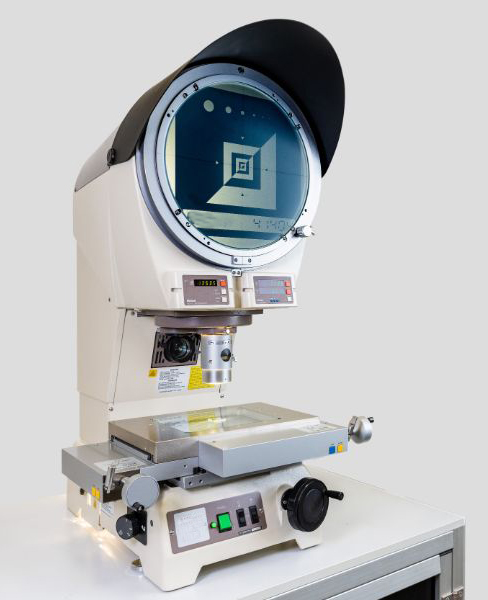

Nanotech Test & Measurement Solution offers Profile Project with Screen Dia of 300mm & 500mm.

Those are bench-top-based optical profile projector that offers high-quality images to precisely measure a feature’s X-Y coordinates. We can get images of the test sample on 300mm & 500mm screens, enabling accurate data capture from the stage.

Some of the Features of Profile Projector:

It is for 2D & linear measurement

Travel: 250x150x150mm

Straight and angular probes

5-500X, high precision stages

0.5 micron resolution

high contrast and crisp images, Episcopic Diascopic, & Contour illumination

Nanotech Test & Measurement Solution also provides various type of Hardness Tester on behalf of the various OEM. In this segment, we have Fully Automatic, Rockwell Hardness, Brinell Hardness, Vicker Hardness, Micro Vicker Hardness & Universal Hardness, types of Hardness Testers in Digital type.

Fully Automatic Microhardness Tester: This type of hardness system travels to the test sample location with < 1 micro accuracy, it indents, then makes autofocusing and measures the indent, same time it polts the hardness graph and based on the cut off value calculates the case depth value. We can perform Vickers, Knoop, Brinnel Low load with ASTM E 384 , ISO 6507, JIS B 7725, JIS B 7734

Rockwell Hardness Tester: Digital Rockwell Hardness tester is for accurate measurement of hardness in metal parts or components in Rockwell scales such as HRC, HRB, HRA, HRE etc. We have this hardness tester with various scale & Standard of ASTM E 18, ISO 6508, JIS B 7726

Vicker Hardness Tester: Nanotech TMI offers Digital Vickers hardness tester as well in our product portfolio. The hardness of a material is determined by forcing an indenter into the surface of a material under a light load; usually, the indentations are so small that they must be measured with a microscope. We can perform the test under ASTM E 384, ISO 6507, JIS B 7725, JIS B 7734

Micro Vicker Hardness Tester: In this type of Hardness Testers, we are capable of performing precise measurements of hardness numbers using state-of-the-art image processing technology. We can perform a variety of tests from soft metals to hardened steel with high accuracy. For loading and unloading, they have a motorized cycle and for load selection, manual machines have external knobs.

We offer wide range of precision measuring instruments. It is the most comprehensive range in metrology equipment with excellent quality. We sell these items from various OEM to meet our clients requirements:

- Outside Micrometer: Regular product of outside micrometers – The frame is provided with a heat insulating cover. Coated frame type. Large-size micrometers are also available. – Measuring range: up to 1000mm in standard specification.

- Digital Micrometer: 1/1000mm graduation‚ Standard model: waterproof type – Measuring range: up to 300mm. Bigger sizes of Measuring range: more than 300mm also available.

- ABS Digimatic Caliper: Abundant lineup of calipers such as models with no output and with carbide-tipped jaws. Further smooth slider surface.

- Dial Caliper: Dial caliper that provides a minimum reading of 1/100mm – The titanium-coated main scale excels in durability.

- Digimatic Indicator IDC: Allows arbitrary calculation compensation of spindle displacements. – Widely used for curvature measurement‚ bore diameter measurement‚ etc.

- Portable Surface Roughness Tester Surftest SJ-210: Light‚ compact body and simple operation – Displays waveforms on the color LCD screens.

- Rectangular Gauge Block Set: Practical master gauge for dimensional measurement – Two types of steel and ceramic gauge blocks are available. – Four classes of Class K‚ Class 0‚ Class1‚ and Class 2.

- Standard Bore Gauges: Cylinder gauges for measuring inside diameters between 18 and 400mm – Covered with total 7 models (Carbide-tipped measuring faces are available.) Different models like Shallow Hole Type Bore Gauge, Bore Gauge with Micrometer Head and Small Bore Gauge which Supports measurement of small inside diameters between 0.95 and 18mm are also available

- Borematic Holtest: Allows stable measurement of inside diameters with three contact points

- High-accuracy Height Measuring Instrument – Linear Height 2D: Extraordinarily high-accuracy and abundant measuring functions – Air-floating travel and automatic measurement. High-performance height measurement instrument with a sense of height gauge.