Environment Test Solutions

We, Nanotech Test & Measurement Solution, offers various range of Environmental Test Chambers. In this we have various types of chambers based on Sizes, Performance & Applications from simple bench-top climatic chambers to advanced high-tech systems, such as thermal vacuum chambers for aerospace applications and calorimeters.

Various industrial fields needs to use such Simulated Environmental Tests to meet specific requirements as per various International Standards. Testing the specimen in various environment tet conditions as per Standards, we can improve the reliability and reduce the risks associated with the development of new products.

Our offered Environmental Chambers comes with 02 types. Based on the application, we are able to provide chamber with only Temperature Testing whereas we also offers Chamber with Temperature & Humidity as well in single chamber. Those chambers are suited to material testing under dynamic conditions.

Our offered Chambers come with rapid alternation speeds of around 5 K/min~ 20K/Min which is capable to simulate the conditions for complex temperature profiles -70 °C to 180 °C.

Those climate chambers also simulate Humidity in range of 10% ~ 98% Rh along with simulation of various temperature

The programmable controller helps to run the test with various conditions of temperature, humidity with respect to time for long run from hours to months continuously.

Thermal Shock Chamber as part of Climatic chambers is widely being used for providing Strong Thermal Shocks by passing by passing the Test Samples suddenly and repeatedly from a hot temperature zone to a cold one. In Thermal Shock Chamber, there are 02 types of Zone available named as Cold Zone & Hot Zone. Cold zone is capable to have temperature upto -70deg C & Hot Zone is capable to withhold temperature range upto 180deg C.

The specimen travels from Hot Zone to Cold Zone through Basket transfer in 08~ 10 sec. Having exposure to repeated cycles cause large expansions and contractions in volume, the material could undergo strong mechanical stresses and sometimes break.

It generates up to 390g per hour, generates steam volume up to 1 gallon, and conducts tests in accordance with JIS D 4502/4504-1994, ISO 3470-1989(E), EEC 661, and SAE J953 standard.

We, Nanotech Test & Measurement Solution, offers Altitude Tests Chambers which is combination of temperature and altitude environments with optional humidity for simultaneous environmental testing. An This combination of elements allows precise simulation of real-life conditions a product might encounter at various altitude levels

Those climate chambers simulate the operating conditions of test samples that operates in environments where the atmospheric pressure decreases over time. In Aeronautics Industry, it is essential to test the parts or components with an effective combined control of temperature and pressure in order to simulate the exact altitude above sea level.

Usually Altitude Test Chambers is available in Thermostatic (temperature and pressure control) and Climatic (temperature, pressure and humidity control) in various capacity & sizes.

Depending upon the application & type of test sample, we can achieve the altitude of 100,000 to 150,000 feet with temperature range of -70deg C~ 180deg C.

In current trend, the automotive industry accelerates electronic multi-functions ISO26262 and IEC61508 require high environmental stress that is generated by thermal shock chambers for higher reliability of vehicle equipments.

The Environmental Test System is located above the vibration test system, which is equipped with a vertical and horizontal table in front of and behind the vibration test equipment, to allow the chamber to slide and move up and down to perform vertical excitation combined testing and conventional horizontal excitation combined testing at ambient temperature in a single unit.

The vertical and horizontal tables are separated, enabling large displacement and high speed vibration, which is ideal for combined environmental testing of automotive parts, car electronics, wire harnesses, plastic moulded parts, and more

The chambers are available in temperature-only or temperature and humidity configurations. Rapid thermal change rates of 5°C up to 30°C are available. These environmental chambers can become vibration chambers when seamlessly integrated with shaker or repetitive shock vibration table.

HALT HASS is Accelerated testing which is used to quickly detect design and manufacturing defects. Typically, a series of individual and combined stresses such as multi-axis vibration, rapid temperature cycle and product feed cycle are applied in increasing phases or intensities (well beyond those expected in the field). This leads to early product maturity.

Halt & Hass test chambers are specifically designed to perform accelerated environmental testing by applying very high environmental stress of Triaxial vibration, Rapid climate cycles & Humidity.

The benefits of HALT HASS is that:

- It Significantly reduced production costs

- Timely corrective action for design problems

- Reduced engineering costs

- Reduced warranty costs

- Rapid product placing on the market

Corrosion is a chemical or electrochemical reaction between a material and its environment. This process causes the deterioration of the product and the loss of its initial characteristics.

Climatic chambers for corrosion testing can help predict the resistance of materials in order to estimate the life cycle of the components, compare different products and evaluate the behaviour of a coating in a specific corrosive environment

We provides various range of Corrosion Test Chambers. Salt Spray Tests is traditional test in corrosion test chambers,, in compliance with the main international standards and regulations. VDA, SAE J2334 and the Kesternich test are available as standard options.

BENEFITS

Top-loading salt solution

Height-adjustable feet

Flowmeter for reading the salt solution flow rate

Transparent and ergonomic hood, with powered opening, to prevent drops of salt solution from falling on the specimen

We offers various range of Walk In Chambers. Those are Prefabricated Modular Chambers combine the guarantee of reliable and reproducible tests with the advantage of an easily configurable product, quick to assemble and easy to renew in case of future needs not considered at the time of purchase. The project is based on the four standard elements of a prefabricated chamber to be composed and coupled to create the most suitable configuration for the customer’s needs:

- Machine Group

- Air treatment units

- User Interface

- Panel structure

These chambers can be supplied with the new ecological refrigerant gas. Based on the application & requirements, we can design the large walk in chamber to meet Temperature & Humidity with desired performance by using various capacity of Heaters & Compressors etc.

We make it possible to conduct tests in controlled temperature and humidity conditions similar to those in which the battery will operate during its service life. Battery charge and discharge testing cycles are a key activity in laboratories doing battery testing. The instruments used for these tests often subject batteries to demanding and long-lasting testing cycles.

In addition to the standard line, we are able to offer customized solutions to meet various testing applications. In addition to the range of standard chambers for temperature and relative humidity tests, we are able to provide chambers that meet all the test requirements for battery cells, modules and packs of various sizes and with various temperature and relative humidity ranges, to meet the differing needs of customers in this industry.

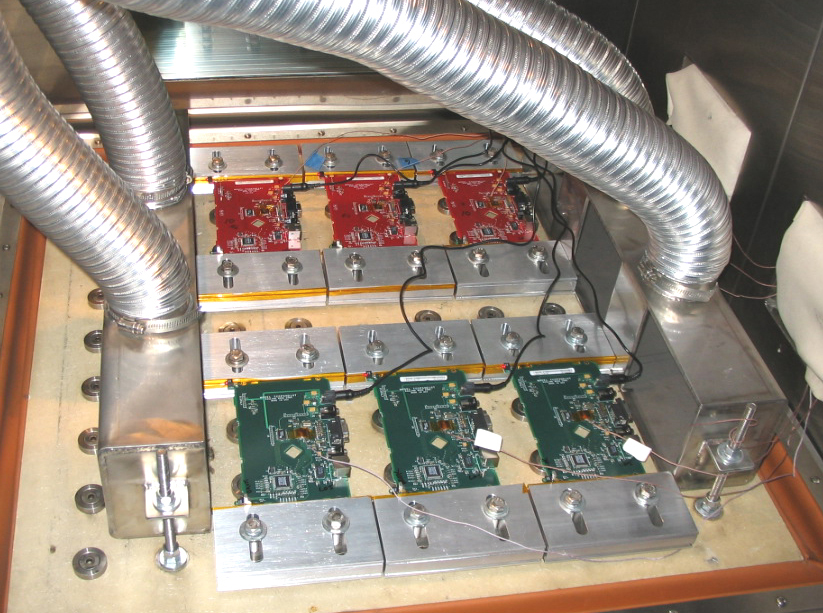

Example of a battery test chamber customized according to the customer’s requests.

- Inside working volume: 9000 liters

- Temperature range: -60°C / +150°C

- RH range: 10% to 95% in the range of +5°C to +90°C